Mechanical Belt Fastening involves the use of mechanical belt fasteners (also called conveyor belt lacing) to join open end conveyor belts. Mechanical belt fasteners combine strength and durability with affordability and easy installation. Through Flexco conveyor belt mechanical fastening, the production loss is minimized and fastening reduces downtime when compared to the endless conveyor belts and belt vulcanizing process which is time consuming

We can arrange for supply of belt fastening tools to the client with which they can do the fastening without our help for which we will be giving initial training.

MECHANICAL BELT FASTENERS VS. VULCANIZATION

Mechanical Belt Fastening is the process of joining conveyor belt ends by metal hinges or plates. Vulcanization is the process of joining belt ends through heat or chemicals. The vulcanization of heavy-duty conveyor belts – whether hot or cold—is a time-consuming process that requires special skills, expensive equipment, extreme accuracy in the cutting and stripping of belt ends, and a thorough knowledge of solvents, bonding materials, and compatible cover and fill materials. Mechanical Belt Fastening involves the use of mechanical belt fasteners (also called conveyor belt lacing). Mechanical belt fasteners combine strength and durability with affordability and easy installation.

HEAVY-DUTY BELT FASTENER TYPES

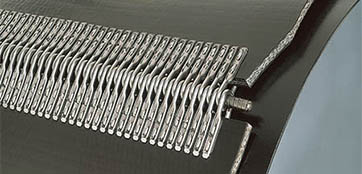

In heavy-duty applications like coal, cement, mining, and aggregate, there are two main belt fastener types: Hinged Plate and Solid Plate. Hinged plate fasteners, often used with small pulleys, are installed into each end of the belt and then joined together and held in place with a pin. Solid plate fasteners consist of one plate that is installed into both ends of the belt and fastened together. Solid plate fasteners are used with larger pulleys and for applications that require a sift-free splice. These fasteners are installed into the belt using bolts, rivets, or staples (depending on belt type and application) and are available in a variety of metals.

LIGHT-DUTY BELT FASTENER TYPES

In light-duty applications like agriculture, parcel handling, food, and laundry, fasteners are available in hook and lacing styles, are installed into both ends of the belt, and are joined together with a hinge pin. Installation methods vary from machine application to using hand tools, and the fasteners are available in a variety of metals, plastics, and in some cases, food-grade materials. Choosing the proper mechanical belt fastening system is one of the most important steps in splicing a belt. Use the filters at the left to refine your results and find the mechanical belt fastening system that is best suited to your application.

ALUMINUM MBRT6 APPLICATOR TOOL COMPLETE

Specifications

Tool Width (in.) - 36

Fastener Size - BR6

Multiple Guide Blocks Required to Span Tool Width - 7

Weight (lbs) -85.0

CLIPPER® WIRE HOOK FASTENING SYSTEM

The Clipper® Wire Hook Fastening System is designed with a variety of different wire diameters, leg and point lengths, metals, strip lengths, and styles to meet your individual application needs.

Flexco® Bolt Solid Plate Fastening System

Belt Thickness

5 mm - 30 mm

kN/m Max

30 kN/m - 100 kN/m

Min. Pulley Diameter

300 mm - 1220 mm

Flexco® Bolt Hinged Fastening System

Belt Thickness

6 mm - 16 mm

kN/m Max

33 kN/m - 52 kN/m

Min. Pulley Diameter

152 mm - 230 mm

Flexco® Rivet Solid Plate Fastening System

Belt Thickness

6 mm - 24 mm

kN/m Max

70 kN/m - 140 kN/m

Min. Pulley Diameter

350 mm - 900 mm

Flexco® Rivet Hinged Fastening System

Belt Thickness

3 mm - 25.5 mm

kN/m Max

60 kN/m - 350 kN/m

Min. Pulley Diameter

127 mm - 1050 mm

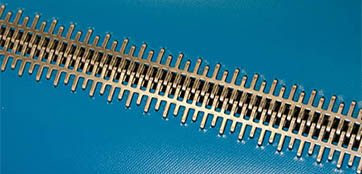

Flexco® Staple Fastening System

Belt Thickness

6 mm - 14 mm

kN/m Max

114 kN/m - 140 kN/m

Min. Pulley Diameter

230 mm - 300 mm

Anker® G Series™ Fastening System

Belt Thickness

1.5 mm - 5 mm

kN/m Max

17 kN/m

Min. Pulley Diameter

40 mm - 75 mm

Anker® Laundry Patch Fastening System

Belt Thickness

2 mm

kN/m Max

Not Applicable

Min. Pulley Diameter

25 mm

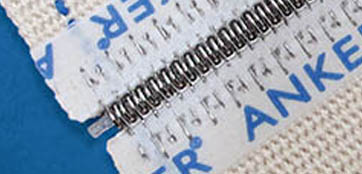

Anker® Spiral Lace Fastening System

Belt Thickness

1.6 mm - 4.6 mm

kN/m Max

8.7 kN/m

Min. Pulley Diameter

10 mm - 15 mm

Clipper® Wire Hook Fastening System

Belt Thickness

Up thru 10 mm

kN/m Max

35 kN/m

Min. Pulley Diameter

24 mm - 175 mm

Clipper® G Series™ Fastening System

Belt Thickness

1.5 mm - 5 mm

kN/m Max

17 kN/m

Min. Pulley Diameter

40 mm - 75 mm

Clipper® Laundry Patch Fastening System

Belt Thickness

2 mm

kN/m Max

Not Applicable

Min. Pulley Diameter

25 mm

Alligator® Staple Fastening System

Belt Thickness

1.5 mm - 6.4 mm

kN/m Max

17 kN/m - 35 kN/m

Min. Pulley Diameter

50 mm - 102 mm

Alligator® Lacing Fastening System

Belt Thickness

Up thru 12.7 mm

kN/m Max

4.3 kN/m - 35 kN/m

Min. Pulley Diameter

25 mm - 356 mm

Alligator® Rivet Fastening System

Belt Thickness

5 mm - 5.8 mm

kN/m Max

52 kN/M

Min. Pulley Diameter

88 mm

Alligator® Spiral Lace Fastening System

Belt Thickness

1.6 mm - 4.6 mm

kN/m Max

8.7 kN/m

Min. Pulley Diameter

10 mm - 15 mm

Alligator® Plastic Rivet Fastening System

Belt Thickness

Up thru 3.2 mm

kN/m Max

7 kN/m - 11 kN/m

Min. Pulley Diameter

38 mm - 75 mm

Alligator® V-Belt Fastening System

Belt Thickness

Not Applicable

kN/m Max

Not Applicable

Min. Pulley Diameter

Not Applicable